It started as a hobby, but it's got out of control. We now have 40+ frames' worth of building experience: Tandems, solos, 29ers, 650bs, full-suspension, fully rigid, mountain and road. Have a look below at some of our recent projects.

Kendal, Cumbria

ABOUT US

GALLERY

Paul

'Guest' Builders

THE BUILD

The front triangle of the frame is tacked together first, with any internal routing added at the same time.

Holes are added for internal routing and aeration of the tubes.

The rear stays are brazed on a separate jig before being mitred to the frame.

Careful alignment is crucial for fittings such as suspension pivot points.

More radical projects have required some modification of our jig.

Big holes in the head tube are light, but this option helps keep distortion to a minimum.

Unusual tube loadings such as those for suspension mounts call for custom external butting of the tubes.

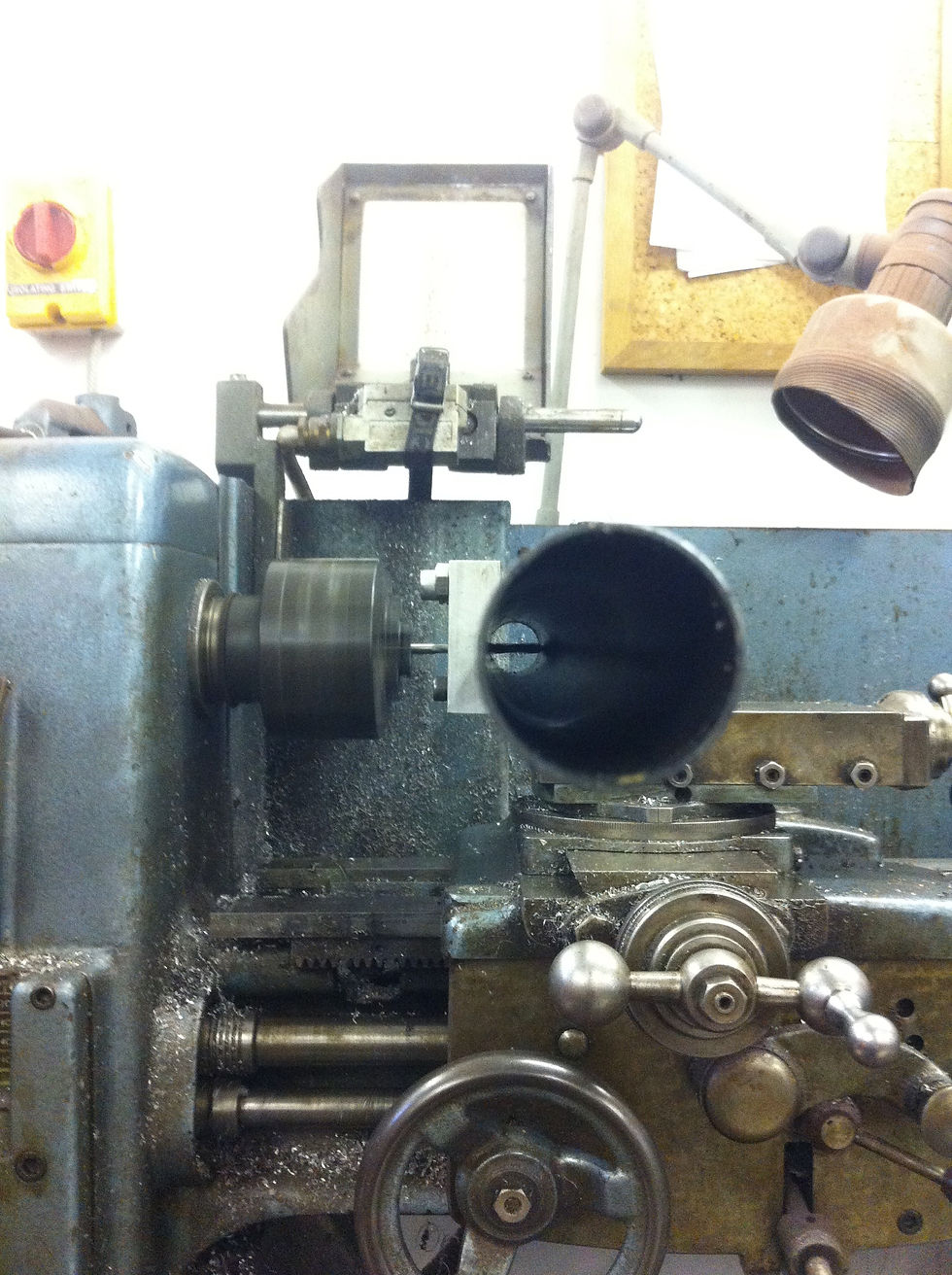

Hand mitring with a file is slow and painful. More jigs - like this one for chainstays - and a holesaw in the lathe help produce reliable and accurate mitres.

A custom jig has sped up the build process hugely, allowing angles and dimensions to be set with a minimum of tape-measure use.

Jig and initial setup

We use a custom homemade jig to build our frames, with angles and dimensions marked on a thick plate aluminium base. Custom fittings mean the jig can be used for a huge range of different frame sizes.

Always nicer to be outside when the weather's good.

Headtube joint with stainless internal cable routing showing. The excess is then trimmed off, leaving a small fillet for strength.

Freshly fillet brazed joint, with some flux left.

Cleaned up bottom bracket joint.

Seat tube joint, with reinforcing sleeve silver soldered in place.

Brazing

Most of our frames are fillet brazed, with small braze-ons attached using higher silver content bronze, which has a much lower viscosity. After brazing there's a small amount of cleanup needed to get a really smooth transition through the joints.

Dropout detail. These dropouts had stainless plates brazed on to minimise paint chipping.

Masking freehand takes a lot of patience.

Went a bit wild with a paintbrush on this one, the idea was to reflect the weather outside...

Painting

All our frames are painted entirely in-house. The process is laborious, with an initial coat of primer followed by plenty of coats of colours, logos and any decals with a couple of coats of lacquer to seal everything in. The end result is worth it (if you like pink...).

Anodised bottom cup and top cup with top cup in progress.

Anodising dye.

Custom Thomson ISP topper.

Custom rear light with batteries concealed in ISP.

Broaching hex flats in a lathe - difficult!

A finished mtb 12mm through-axle ready for anodising.

Other components

With access to an old lathe and a slightly newer mill, the possibilities are pretty much endless. With an anodising bath set up, we can now make alloy parts that are fully sealed from corrosion - and dye them nice colours!